So, What is Computer-Aided Machining?

In simple terms, CAM is a type of manufacturing method that utilises computer software and automatable machinery to create corporeal products.

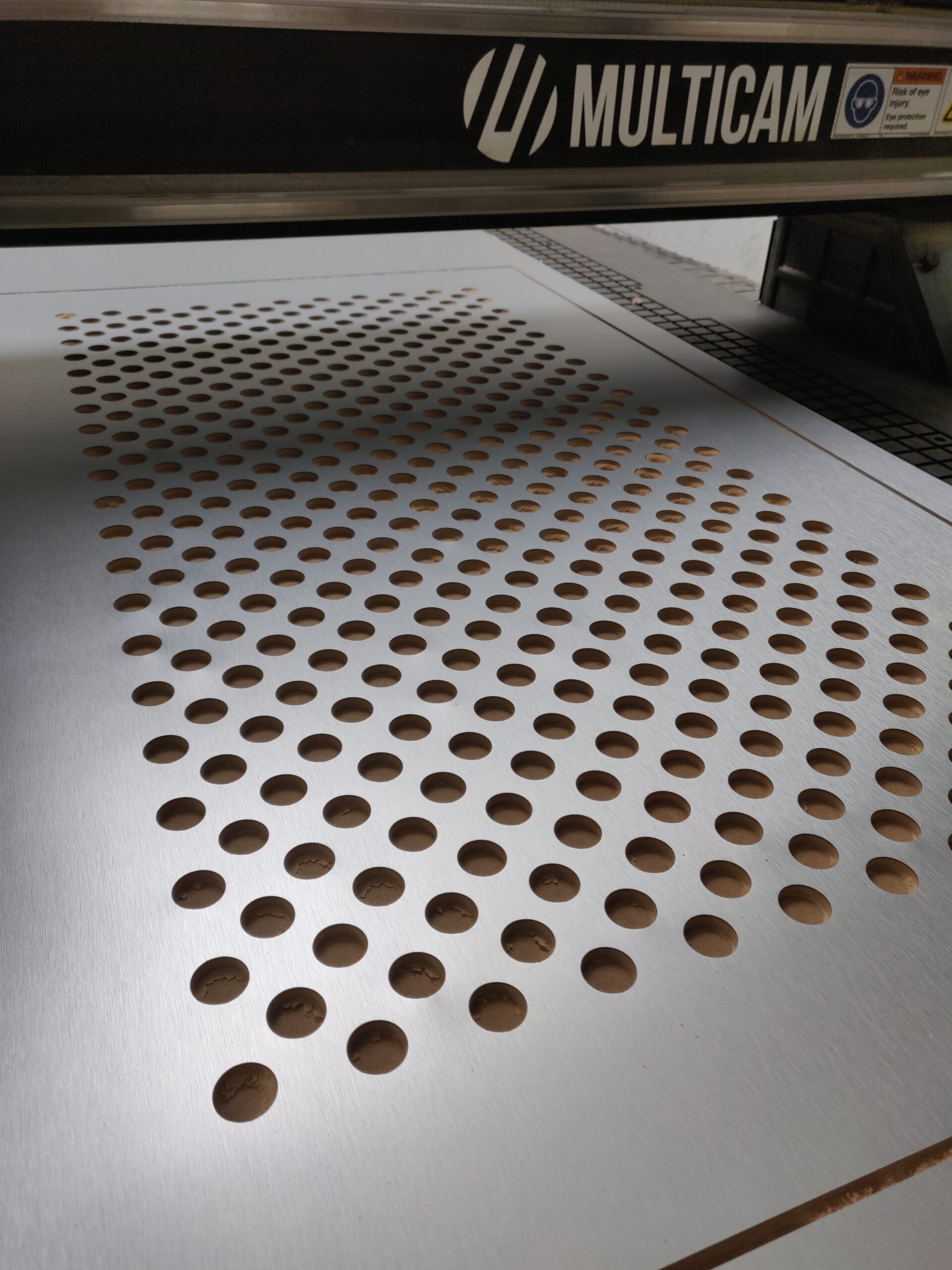

This method is renowned for creating high degrees of accuracy and precision while working, with contemporary machines and software technologies having enabled us to create superior components and achieve far greater control over entire production processes.

A CAM tool uses a basic product model that’s created within computer-aided design (CAD) software packages, with the former converting computer models into a viable language that’s understood by machining tools and subsequently executes the production process.

The process of CAM and its associated technologies can also aid manufacturers with product planning, development management, storage and logistics, improving every stage of the production process from initial design to execution.

Ultimately, the primary objective of CAM is to create new, or enhance existing, manufacturing procedures, with a view to improve efficiency and reduce wastage. It achieves this largely by expediting various manufacturing and production processes (and tooling), while also focusing on reducing energy consumption and the associated operational costs.